Having completed the 'Terrier', gaining experience and confidence in the process, I felt brave enough to purchase a larger and more complex locomotive for my second attempt at construction. The locomotive would be a London & North Western Railway locomotive. The loco chosen was a Class G1 more widely known as a 'Super D'. where the 'Terrier was a six coupled wheel locomotive, the 'Super D' is an eight coupled wheel locomotive and twice the size of the 'Terrier. These locomotives were mainly employed on heavy freight workings.

The kit was produced by David Andrews, who runs a small kit manufacturing company with a name for quality. The kit is manufactured in nickel sliver for the chassis, brass etch for the body and tender and white metal castings for the smaller parts. There is no option but to solder, no hiding behind tubes of epoxy resin with this one. The build started with chassis, which is the normal approach when building kits. Having built the chassis you are able to ensure as you build the body, it does not bind on any moving parts of the chassis. My confidence in building this chassis was much higher than with the 'Terrier'. I took the kit with me for the chassis building weekend at Hobby Holidays. Phil Atkinson who runs Hobby Holidays with his wife Jo, is a very experienced modeller and like Ian Rathbone, accepts commissions to build locomotives. Phil's experience in chassis building, prompted him to design and build a jig, which ensures that the chassis is square and the axle bushes are truly in line. This gives you a one hit approach to a near perfect chassis. Since the tender on this loco also has chassis, the jig was doubly welcome. The jig converts to a rolling road, so that you can insert the electric motor into the chassis, apply the power and confirm you have a chassis that will run freely on the track. Since I intended to build more locos I purchased a jig from Phil. Incidentally, I also purchased from Jo, for the vast sum of £1, a packet of clothes pegs normally associated with dolls houses. These are used to clamp together very small items whilst soldering (not so many burnt figures).

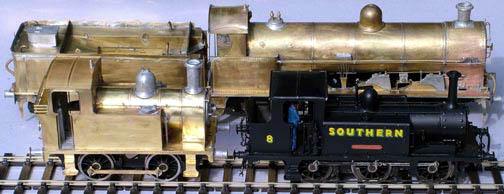

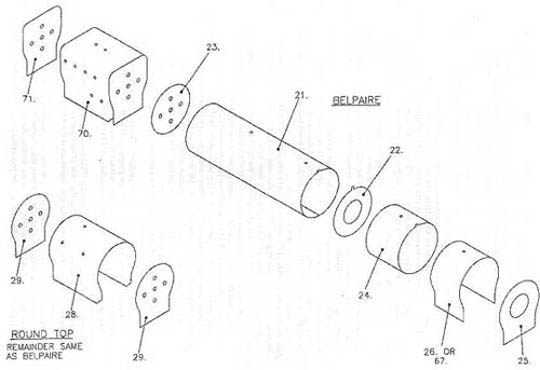

The body of this loco turned out to be far more complicated than that of the 'Terrier'. Look at the picture above, you will see the cab of this loco has a curved roof and sides, also beading around the cab sides and the roof. Yet another learning curve to negotiate. It was also necessary to form the firebox which is just in front to the cab, together with the smoke box at the front, just under the chimney. Phil was able to steer me round that learning curve, by showing how to soften the brass parts supplied for these items, thus simplifying the forming. Completing these elements was most satisfying.

As of May 2007, the build of the model is 99% complete and the outstanding items will be added following painting. Completion to this point was far more satisfying, compared with the same stage of the 'Terrier', despite many frustrations along the way. Much of that satisfaction came from utilizing new found skills, rather than the individual kits.